Whether providing solutions for transmission assemblies or individual components, ODG offers a wealth of knowledge and experience. ODG has the ability to design, develop, prototype, and manufacture which results in a robust cost-effective solution that meets our customers most demanding requirements

- Going beyond just gears, offering a complete one stop solution

- Strong relationships with large profile OEM customers

- Innovative product offerings

- State-of-the-art facilities in close proximity to customers

- Experienced Senior Management Team

- Highly skilled Engineers and Program Managers

- Long history of profitable financial results

- Embracing a green corporate philosophy from customers right through operations “

ABOUT ODG

Founded in 1962 by the Stieber family, Ontario Drive & Gear Limited operates from 2 facilities, with a total of 140,000 sq ft manufacturing footprint in New Hamburg, Ontario. To satisfy the growing demand for its products and innovative developments, ODG has aligned its business strength in two divisions: the Gear and Vehicles. The Gear Division ODG has built a solid reputation for the design and manufacture of quality gears and transmissions and ARGO is known as the world leader in amphibious vehicles. ODG is proud of its people and recognizes they are the basis of the company’s success story. Numerous performance awards from industrial customers are testimonials to ODG’s commitment to customer satisfaction and quality.

Since it’s inception, ODG has been manufacturing quality precision gears and transmissions. For over 50 years we have always put our customers first by exceeding their expectations for quality, delivery and cost.

Beyond just gears, ODG is recognized as a world leader in amphibious all terrain vehicles. The ARGO can travel through the most extreme conditions, and is driven by ODG gears and transmissions.

The ODG Niche

The ODG Market Niche is best defined as:

- Cylindrical gears up to 500mm in diameter

- Manufactured in a High Mix, Low Volume, High Quality job shop environment

- ODG manufactures over 1,000 different and unique SKUs,

- In volumes up to 100,000 units annually

- Up to master gear quality levels AGMA 14 (2000-A88)

- With full engineering capabilities allowing us to Design, Manufacture, Assemble & Test both gear and complete transmission systems

Facility

Quick facts:

- Climate controlled factory designed for gear manufacturing

- Manufacturing floor space of 56,300 sq ft

- Invested over $10M in latest technology over last 5 years

- Employees 129: Engineers 11, Skilled Trades 24

- Began applying lean manufacturing systems in 2008

Lean & Operational Excellence

At ODG “Lean” is beyond just a system or the identification of wastes, it’s about creating value for our customers. Lean defines our people, processes and operating practices, to create a culture that that allows us to achieve our goals and objectives. Our lean foundation is made up of employee involvement and empowerment, training, organization, 5S, and maintenance excellence. Our continuous improvement model focuses on the standardization of work and the “Plan-Do-Check-Act” methodology. When this all combines it leads to flawless execution of operations, allowing us to achieve best in class quality, delivery and cost.

Quality

ODG is committed to excellence, and recognizes that each employee plays an essential part in supplying quality products. ODG is committed to develop, manufacture and deliver products and services that meet or exceed our customer requirements. ODG’s commitment to high quality gears and transmissions is backed by the latest manufacturing technology and a team of professionals dedicated to excellence.

See our quality certificate here:

Environmental

Ontario Drive & Gear Limited is extremely proud of its commitment to minimizing its environmental footprint. We are continually exploring new opportunities that will improve our products and performance, reduce our environmental impact and benefit our local communities. To achieve these goals, we comply with all federal, provincial and municipal environmental laws. To reduce waste and emissions, we utilize material substitution, source reduction and recycling technologies in all of our manufacturing departments and offices. We use energy efficiently and effectively. A prime example of one of our “green” initiatives was the introduction of dry hobbing technology within our gear production facilities, which eliminated the need for oil. At ODG, we believe strongly in our environmental responsibilities. Towards this end we take careful consideration of all policies, practices and even the suppliers we choose to partner with. Our employees are firmly committed to our environmental objectives and, as always, are a key component to our success.

See our environmental certificate here:

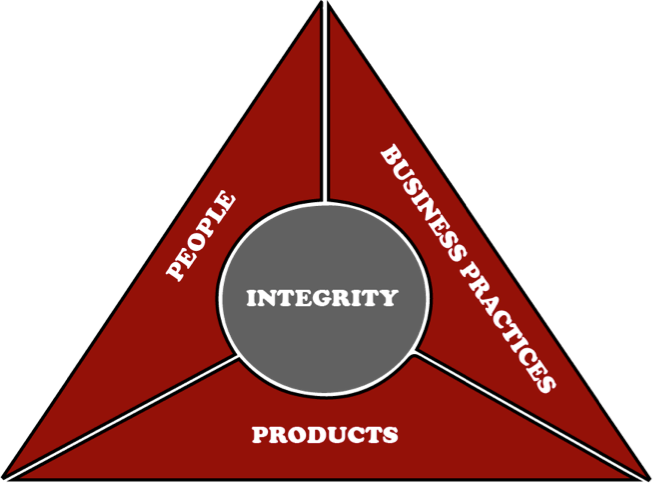

Core Values

People: The Quality of Being Undivided: Unity

Business Practices: The Firm Adherence to a Code of Value: Honesty

Products: An unimpaired condition: Soundness

QUALITY – CONDITION:

- Our People are United

- Our Business Practices are Honest

- Our Products are Sound

People, Business Practices, Products, Integrity